Laser cutting is one of the most precise and efficient methods used in metal fabrication. Whether you’re producing structural components, custom enclosures, or decorative elements, laser cutting delivers clean edges, tight tolerances, and consistent results. But depending on your material and design, there’s an important choice to make: tube laser cutting or sheet laser cutting. Understanding the differences, and knowing when to use each, can help improve quality, reduce costs, and streamline your fabrication process.

What is Sheet Laser Cutting?

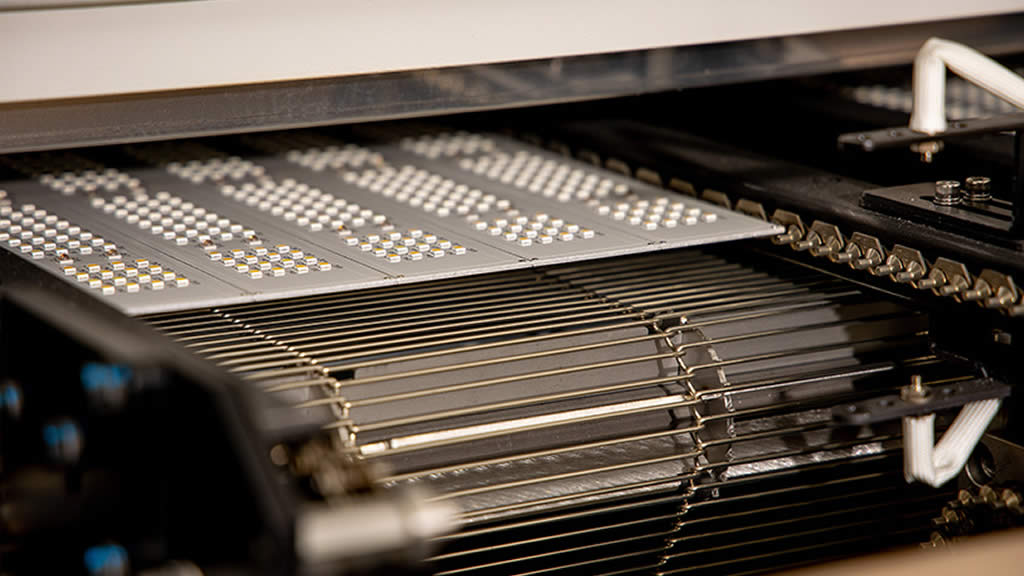

Sheet laser cutting is the process of using a high-powered laser to cut flat metal sheets into desired shapes and components. This technique is ideal for creating parts from sheet metals like stainless steel, aluminum, carbon steel, and more.

Key benefits include:

- Precision and Accuracy: Achieve tight tolerances and detailed geometries.

- Speed: Cut large volumes of parts quickly.

- Material Versatility: Works on a wide range of metals and thicknesses.

- Clean Edges: Reduces the need for secondary finishing.

Sheet laser cutting is often used for flat components like brackets, panels, enclosures, signage, and structural parts.

What is Tube Laser Cutting?

Tube laser cutting is specifically designed to cut round, square, and rectangular tubes, as well as other profiles like angles and channels. It allows for intricate cuts, slots, holes, and notches on tubular materials that would be difficult or impossible with traditional methods.

Key benefits of laser tube cutting include:

- Complex Designs Made Easy: Cut holes, slots, and miters in a single process.

- Precision Fitment: Ensures perfect joints for welding or assembly.

- Reduced Waste: Optimizes material usage and minimizes scrap.

- Streamlined Production: Cuts, drills, and profiles in one setup.

Tube laser cutting is commonly used in industries like automotive, furniture, construction, and architectural applications where tubular components are essential.

When to Use Each?

Knowing when to use sheet or tube laser cutting helps you get precise, efficient results. Sheet is best for flat parts with detailed patterns, while tube works perfectly for shaping round, square, or specialty tubes.

- Use sheet laser cutting for flat parts or components requiring intricate patterns, cutouts, or profiles from flat stock.

- Use tube laser cutting when working with round, square, or specialty-shaped tubes that need precise features or joints for structural frames, supports, or decorative elements.

Need Both?

Many projects require a combination of both tube and sheet laser cutting to complete an assembly. Partnering with a full-service metal fabrication company that offers both capabilities under one roof can save time and reduce handling costs.