Tube Laser Cutting

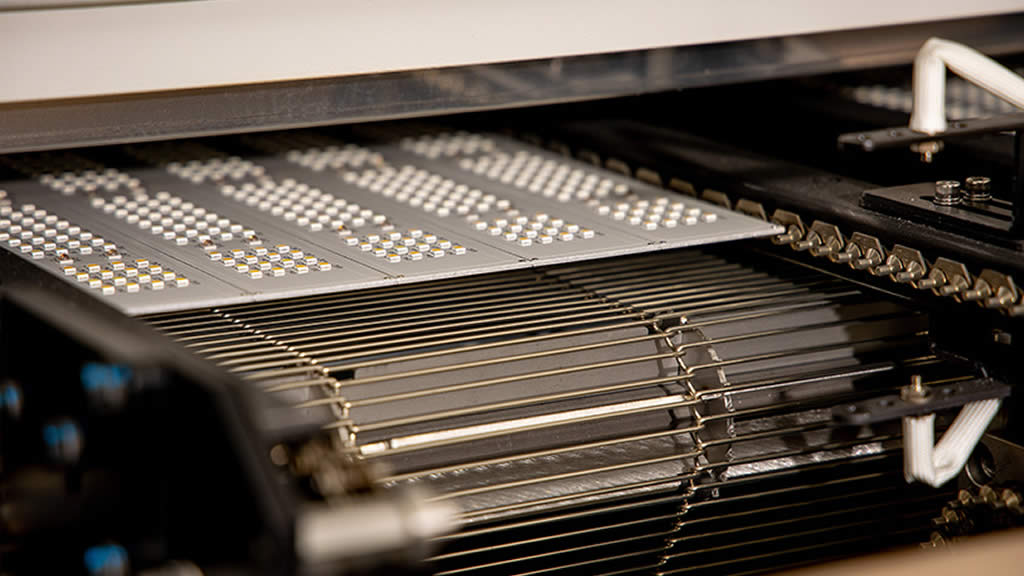

advanced Tube Laser Cutting at CM Fabrication

When it comes to precision metal fabrication, tube laser cutting at CM Fabrication gives you an advanced, efficient solution. Our state-of-the-art laser cutting technology ensures high accuracy, reduced material waste, and faster production times, making us the trusted choice for industries requiring high-precision fabrication services.

Capabilities

- Advanced Cutting Technology: Our tube laser cutting process integrates the latest in computer-controlled automation, ensuring every cut is consistent and meets exact specifications. This advanced technology allows for complex designs, tighter tolerances, and greater efficiency in production.

- Structural Components: Our precision cuts are perfect for creating strong and lightweight metal frameworks ideal for architectural and industrial designs. With clean edges and exact measurements, these cuts ensure seamless assembly and long-lasting structural integrity.

- Specialized Features and Processes: Our tube laser cutting features drilling, slotting, and notching to eliminate secondary machining, chamfering and miter cutting for precise assembly, and etching and marking for easy identification—all with high-speed, distortion-free processing.

- Versatile Materials: We work with a variety of metals, including steel, aluminum, stainless steel, and titanium.This versatility allows us to meet the demands of diverse industries, from aerospace and automotive to construction and manufacturing.

Industries Served

- Automotive: We offer precision-cut components for vehicle frames and structural supports.

- Aerospace: Our high-quality metal parts meet stringent industry standards.

- Construction: We fabricate custom metal tubes for architectural and structural applications.

- Industrial Equipment: We manufacture high-performance components for machinery and production systems.

precision & efficiency: tube laser cutting at cm fabrication

Our tube laser cutting process enhances design flexibility, allowing for intricate cuts, custom patterns, and complex geometries that traditional cutting methods can’t achieve. Whether you need precisely beveled edges for seamless welding or specialized hole placements for easy assembly, our advanced technology ensures every component meets exact specifications. This level of precision helps streamline production and improve overall efficiency, making it an ideal solution for projects that demand both quality and speed.

Why Partner with CM Fabrication?

Choosing CM Fabrication mean working with an experienced team dedicated to quality and precision. Our tube laser cutting services ensure:

- Consistent Quality: Every cut meets exact specifications for superior results.

- Custom Solutions: We accommodate complex designs and specialized requirements.

- Reliable Service: On-time delivery and exceptional customer support set us apart.

Capabilities

Standard Materials: Mild Steel, Stainless Steel, Aluminum, Copper (Fiber) & Brass (Fiber)

Section Loading Lengths

- Minimum Autoloading Bar Lengths:: 10.499’ (3200mm)

- Maximum Autoloading Bar Length: 28’ (8500mm)

- Minimum Manual Loading Bar Length: 7.559” + Gripping Position + Facing Scraps + Part Lengths (192mm +)

- Maximum Manual Loading Bar Length: 28’ (8500mm)

Section Dimension Capability

Round:

- Standard: .472 to 5.512” (12mm to 140mm)

- Optional 6” Manual Lunette: 6.004” (152.5mm)

Square: 0.472” – 4.724” (12mm to 120mm)

Rectangle & Flat Oval:

- Maximum Inscribed Circle: 6.693” (170mm)

- Dimensions: 0.394” to 5.512” (10mm to 140mm)

- Optional 6” Manual Lunette: 5.905” (150mm)

- Minimum Difference Between Sides: 0.197” (5mm)

- Maximum Difference Between Sides: 4.331” (110mm)

Can also cut – Angle, Flat, U, C, and H profiles

We support projects of all types and sizes, working seamlessly with customer-supplied drawings or models. For customers who need design assistance, our in-house CAD designer is available to help create detailed, production-ready files to bring your vision to life.

the CM FABRICATION ADVANTAGE

Choosing CM Fabrication means working with an experienced team dedicated to quality and precision. Our tube laser cutting services offer consistent quality, ensuring every cut meets exact specifications for superior results. Our custom solutions accommodate complex designs and specialized requirements with on-time delivery and exceptional customer support. Contact us today to discuss your project and request a quote!