Fiber lasers have already transformed the metal fabrication industry — but the evolution is far from over. At CM Metals, we stay ahead of the curve by investing in cutting-edge laser technologies that deliver faster, cleaner, and more efficient cuts. As we look to the future, fiber lasers are set to get even smarter, more powerful, and more adaptable.

One major trend is the continued integration of automation and artificial intelligence. Fiber lasers are becoming more intuitive, with sensors and software that allow machines to “learn” from each cut. This means fewer errors, faster setup times, and more consistent results. As AI becomes more embedded in laser systems, fabricators will be able to produce complex parts with unprecedented precision — even on tight deadlines.

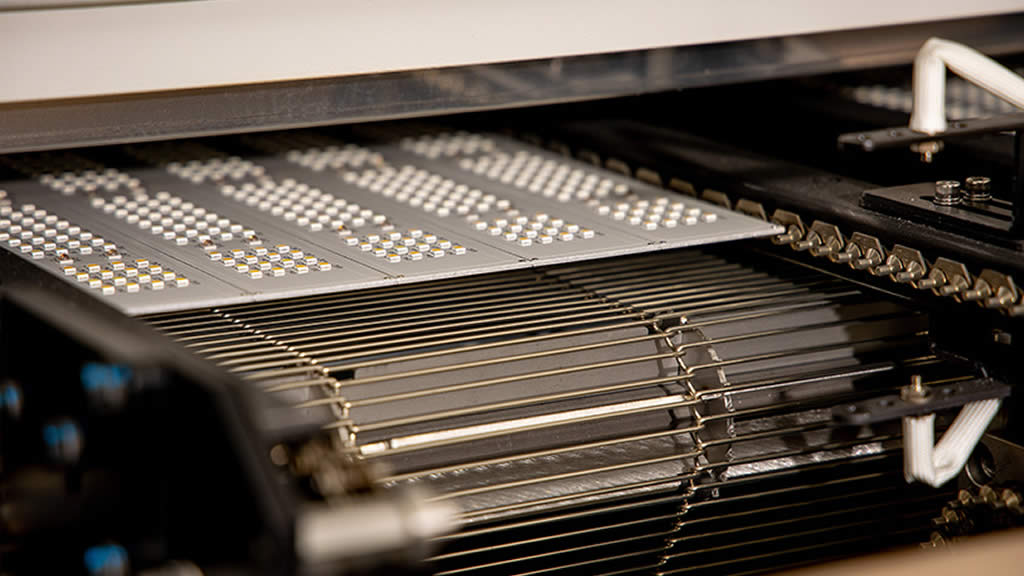

Another big development is the increasing power and versatility of fiber laser machines. Where 2kW or 3kW lasers were once the norm, today’s systems can exceed 10kW — enabling high-speed cutting of thicker materials without sacrificing edge quality. This opens the door to new applications across automotive, aerospace, construction, and more.

Additionally, fiber lasers are becoming more environmentally friendly. Unlike older CO2 systems, fiber lasers are more energy-efficient and produce less waste heat. As more industries look for ways to lower their environmental footprint, fiber lasers offer a powerful way to cut carbon emissions while improving productivity.

At CM Metals, we see fiber lasers as more than a tool — they’re a strategic advantage. By continuing to invest in the latest technology, we ensure our customers benefit from faster turnarounds, lower costs, and precision that meets the highest standards.

Curious how next-gen fiber lasers could support your business? Get in touch with CM Metals — and let’s build something remarkable, with tomorrow’s tech powering today’s parts.