In manufacturing, accuracy isn’t just important—it’s everything. That’s why CM Metals offers precision laser-cut fixtures and jigs that make welding and assembly faster, safer, and more consistent. Whether you’re producing one prototype or thousands of units, smart fixturing can transform your workflow.

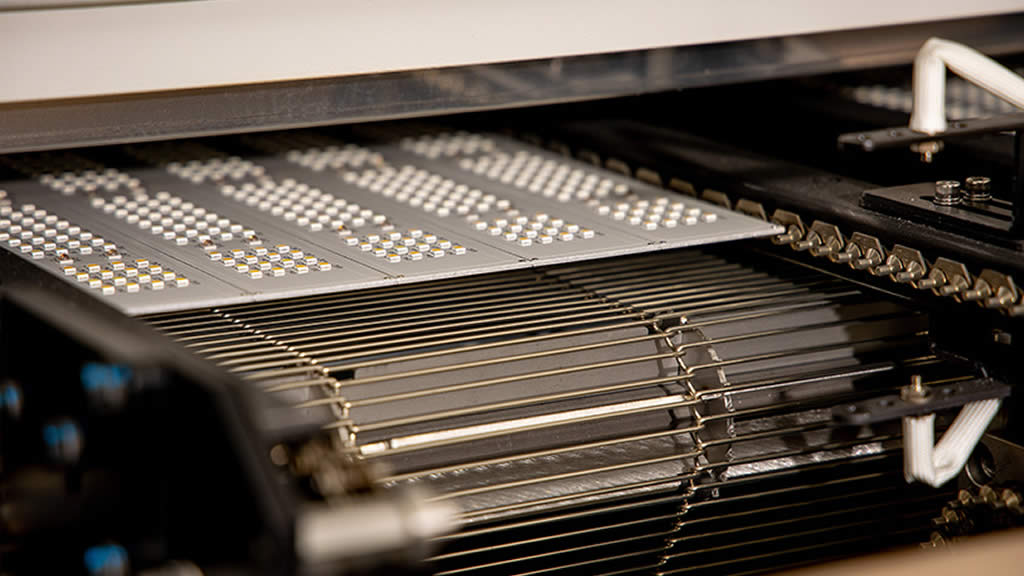

Fixtures and jigs are critical tools that hold components in place during fabrication. When they’re designed and cut with precision, they help welders achieve better alignment, reduce distortion, and avoid costly rework. At CM Metals, we use our fiber lasers to cut fixture components with exact tolerances, ensuring repeatability and durability even in demanding production environments.

Custom fixtures can dramatically reduce time on the floor. When a welder doesn’t have to constantly check alignment or measure by hand, the process becomes more efficient—and results improve. Assembly jigs offer the same benefit, especially when working with parts that must be joined at precise angles or tolerances.

We’ve helped clients in industries ranging from automotive to agriculture speed up their production cycles by creating custom, laser-cut fixturing solutions tailored to their needs. We work with your CAD files or create new designs in-house, using laser accuracy to deliver fixtures that fit your process—not the other way around.

If your team is still relying on makeshift jigs or worn-out templates, now’s the time to level up. CM Metals can help you design, fabricate, and implement fixtures and jigs that improve output, boost quality, and simplify every shift.

Let’s make your shop floor smarter. Reach out today to get started on custom laser-cut fixturing that supports your success.