At CM Metals, precision and efficiency are at the core of everything we do — and laser automation plays a huge role in delivering both. When it comes to metal fabrication, even the smallest errors can lead to costly waste. That’s why we’ve invested in automated laser cutting systems that not only improve cut quality, but significantly reduce scrap and save our customers money.

Automated laser cutting reduces human error by relying on advanced CNC controls and programming to guide the cutting head with pinpoint accuracy. These systems can maintain tight tolerances across long runs, ensuring each part is cut exactly to spec. That means less wasted material, fewer rejected parts, and fewer headaches for our clients.

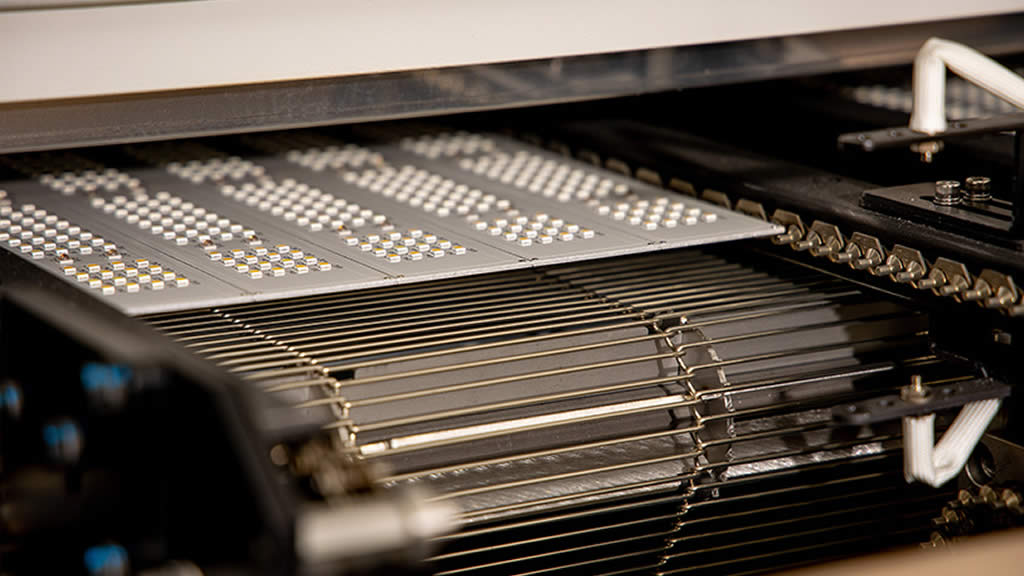

But automation doesn’t stop at cutting. At CM Metals, we use automation throughout the laser workflow — from part nesting software that maximizes material usage to auto-loading equipment that speeds up production and reduces labor costs. The result? Faster turnarounds, more consistent quality, and better cost control for every project.

Reducing scrap isn’t just about cost — it’s about sustainability too. Less waste means less material going to landfills and a smaller carbon footprint for your project. For companies prioritizing ESG goals or simply looking to operate more efficiently, partnering with a fabricator that uses laser automation makes sense on every level.

If you’re tired of over-ordering material, getting inconsistent parts, or spending too much time reworking components, it’s time to see what automation can do for you. Contact CM Metals today to learn more about how our advanced laser cutting capabilities can streamline your next project — and save you time and money in the process.