Rapid Prototyping

From Concept to Prototype: Rapid Prototyping at CM Fabrication

We believe a great design deserves a concrete first step. That’s where rapid prototyping at CM Fabrication comes in. Bridging the gap between your vision and a tangible representation, we use cutting-edge fabrication technologies to transform concepts into real-world models with incredible speed. Our contract manufacturing rapid prototyping services help with the development of new products, allowing you to quickly test designs, refine functionality, and ensure ease of manufacturing before full-scale production.

Accelerating Innovation: The Power of Rapid Prototyping

Traditional prototyping methods can be time-consuming and expensive. This can hinder the design process and slow down innovation. Rapid Prototyping flips the script. This advanced approach allows us to create physical 3D models of your design quickly and efficiently. These prototypes give you the power to:

- Visualize Your Design: Imagine holding your concept in your hands, examining its form and functionality in a tangible way. Rapid prototyping allows you to experience your design in a completely new light, fostering a deeper understanding and appreciation for its potential.

- Facilitate Early Feedback: Don’t wait until production to discover design flaws or areas for improvement. Rapid prototypes provide valuable feedback loops at an early stage. Gather input from stakeholders, identify potential issues, and refine your design before investing in full-scale manufacturing.

- Refine and Iterate: Rapid prototyping allows for quick and cost-effective design modifications. Test different functionalities, adjust dimensions, and experiment with various materials – all within a rapid iterative cycle. This ensures the final product is not just good but truly exceptional.

A Spectrum of Technologies: Tailored Prototyping Solutions

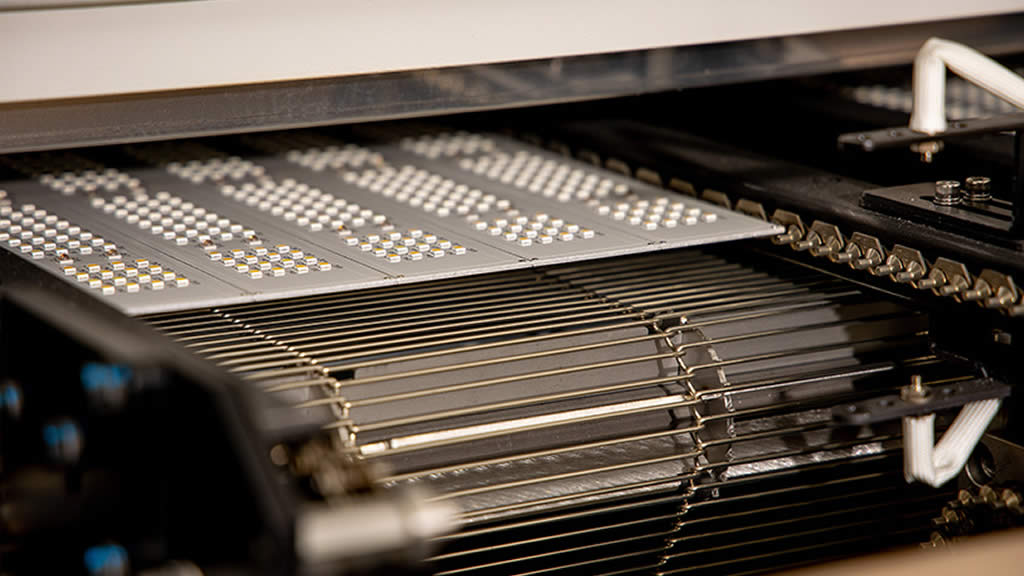

CM Fabrication boasts a diverse range of rapid prototyping technologies. This allows us to create prototypes that meet the specific needs of your project. Whether you require a high-fidelity model for aesthetic evaluation or a functional prototype to test movement and assembly, we have the right tools for the job. Some of the technologies we utilize include:

- 3D Printing (FDM, SLA, SLS): Creates intricate and detailed models with a wide range of material options.

- CNC Machining: Produces highly accurate and functional prototypes from various materials.

- Milling: Achieves precise cuts and shaping for complex components with tight tolerances.

- Tube & Sheet Laser Cutting: Fabricates custom metal parts with exceptional accuracy and clean edges, ideal for prototyping and final production.

- Powder Coating: Enhances durability and aesthetics with a high-quality, protective finish for metal prototypes.

Beyond Speed: The Value of Expertise

Our rapid prototyping expertise goes beyond simply operating the machines. We work closely with you to understand your specific prototyping goals and recommend the most appropriate technology. Our team then meticulously translates your digital designs into precise instructions for the machines, ensuring the final model accurately reflects your vision. Additionally, we offer contract manufacturing to streamline operations, reduce costs, and maintain high-quality standards while focusing on innovation and market expansion.

By incorporating rapid prototyping into your design process at CM Fabrication, you gain a powerful tool to accelerate innovation and achieve superior results. We are committed to helping you turn your concepts into reality, faster than ever before.