At CM Fabrication, we believe that speed and precision can—and should—go hand in hand. That’s why we’ve built a precision fiber laser cutting workflow designed to move from quote to finished parts in as little as 24 hours. When your business relies on rapid turnarounds, you need a fabrication partner that doesn’t just meet deadlines but beats them.

It all starts with your laser cutting quote request. Whether you send us a drawing, CAD file, or even a sketch, our team quickly reviews the design and materials required. We use advanced quoting software and our years of experience to return accurate pricing and lead times, often within the same business day.

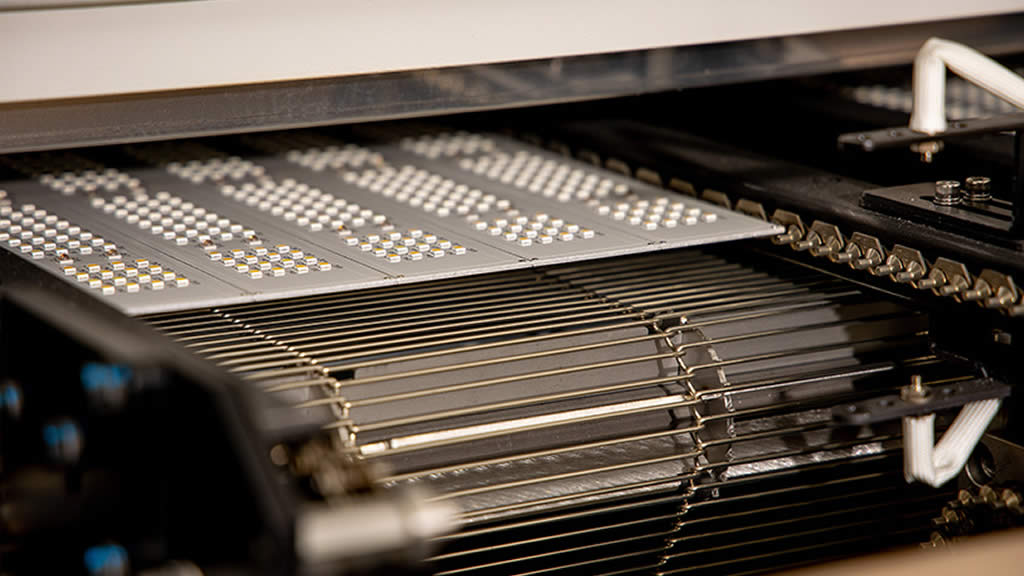

Once the quote is approved, we start creating. We net your file is into a cutting program using software that optimizes every inch of raw material, minimizing waste. Then, we send the program directly to our state-of-the-art fiber laser cutting machines. These machines are capable of tight tolerances and rapid throughput, producing parts with clean edges and repeatable accuracy.

Laser Cutting quotes

We maintain a deep inventory of metals on site, from aluminum and mild steel to stainless and specialty alloys, so there is no delay waiting on materials. Our skilled team cuts, deburrs, inspects, and packages each job for delivery, often within 24 hours.

This precision laser cutting workflow isn’t just about speed: it’s about reliability. Our clients count on us to hit production deadlines, avoid bottlenecks, and deliver quality parts the first time. CM Fabrication has the people, the technology, and the process to deliver fast, reliable results, whether it’s a one-off prototype or a full production run.

Need your project turned around in a hurry? Let’s talk. Request a quote today and see how fast 24 hours can really be.