When it comes to research and development, speed and flexibility are critical. Getting prototypes into your hands—and your customers’—faster can mean the difference between leading the market or falling behind. One of the most efficient tools in accelerating product development is laser cutting, particularly tube laser cutting.

Why Laser Cutting is a Game Changer for Prototyping

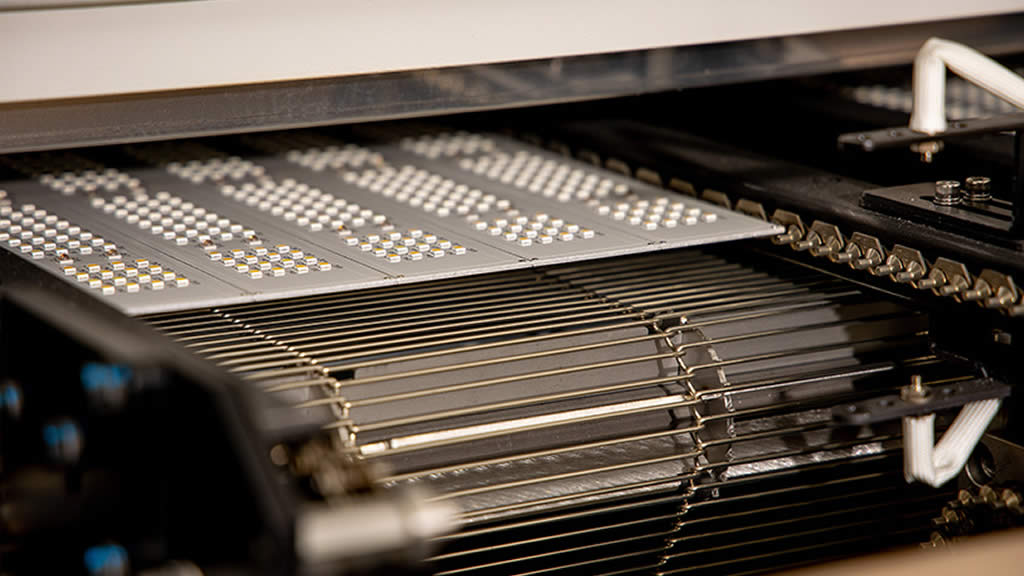

Laser cutting has transformed the prototyping process by enabling fast, accurate cuts without the need for hard tooling. This allows engineers and designers to iterate quickly, test multiple designs, and move to production faster.

For flat parts and enclosures, sheet laser cutting provides precision and versatility. But when your prototype includes structural elements, frames, or components made from round, square, or specialty tube, tube laser cutting becomes essential.

The Benefits of Tube Laser Cutting in Prototyping

Here’s why it’s a powerful asset in R&D:

- Rapid Design Changes: Tube lasers can process complex cuts, holes, and notches in a single setup, making it easy to refine prototypes without long lead times.

- Precision and Consistency: Even for one-offs, laser cutting delivers production-level accuracy, giving you realistic prototypes that reflect the final product.

- Reduced Fabrication Time: Combining cutting, drilling, and profiling into one step saves valuable time during early development phases.

- Material Efficiency: Optimize nesting and minimize scrap, reducing material waste even during short runs.

Supporting Innovation from Concept to Production

Prototyping with tube laser cutting not only shortens the R&D timeline but also allows manufacturers to spot design flaws, test assembly fit, and streamline future production methods. It’s a smarter way to move from concept to market-ready product.

At CM Fabrication, our tube and sheet laser cutting services are built for speed, precision, and flexibility, making us an ideal partner for companies looking to innovate faster. Whether you need a single prototype or a short production run, our advanced laser cutting technology helps keep your project move forward.